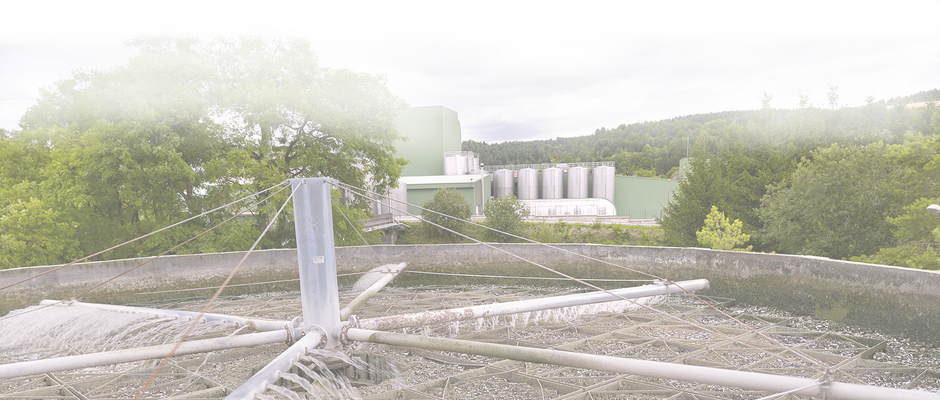

The Environment

The Environment and Safety are amongst the key preoccupations at Fromagerie Henri Hutin.

The Environment : The waste water generated by production is treated in our own treatment station in order to preserve the natural surroundings.

As for the waste, it is sorted and then shipped to subsidiaries specialised in environmentally friendly waste processing.

ISO 14001 certification was obtained in 2004, showing our commitment to everyone.

ISO 14001 certification was obtained in 2004, showing our commitment to everyone.

Staff safety: Prevention is the foundation of our safety management. The appropriate safety rules adopted must be applied by everyone: everyone is responsible

(and regularly made aware of their responsibilities) for their own safety and for that of their colleagues. Health and wellbeing at work depend on this.

OHSAS 18001 certification was obtained in 2007 vouching for the effectiveness of our organisation for preventing risks and ceaselessly improving our performance.

OHSAS 18001 certification was obtained in 2007 vouching for the effectiveness of our organisation for preventing risks and ceaselessly improving our performance.

R&D Innovation

Innovation has always been a priority in the history of the Fromagerie Henri Hutin.

Our R&D Team has always worked to meet our customers' needs, not only by showing a high degree of creativity but also by developing solutions for ensuring the quality of our new products.

All this thanks to the equipment specially designed for the cheese plant.

Our R&D is responsive owing to its closeness to the production teams, and this makes it possible to launch the manufacture of new products quickly on a large scale.

An additional asset is the Hochland group's international presence, which facilitates the development of original solutions.

The existence of three different cheese technologies (Soft Ripened Cheeses, Spreadable Fresh Cheeses and Pressed Soft Ripened Cheeses) side by side on a single production site offering virtually unrivalled technical possibilities on this scale.

Quality

Our plant is certified IFS and BRC Food. These references guarantee controlled production regarding food safety, processes, as well as the qualification of our staff.

At the Fromagerie Hutin, quality is a state of mind based on continuous improvement and creativity. Our goal is to provide the consumer with a healthy, high-quality product while guaranteeing a delicious savoury experience.

Production Tool

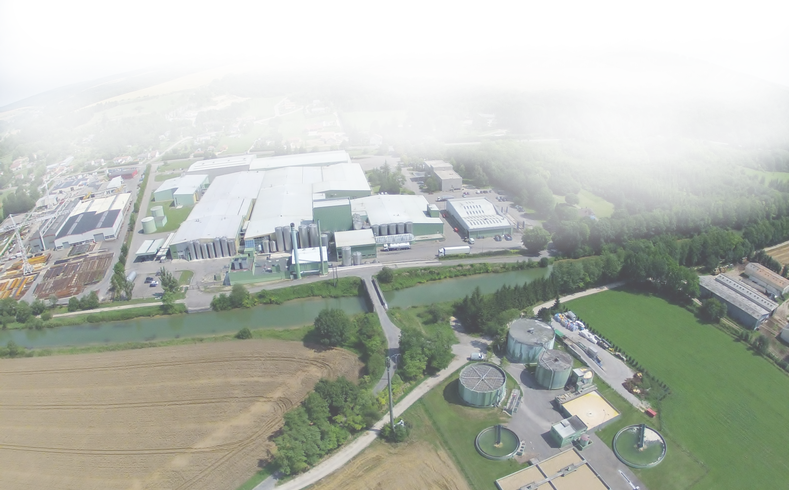

General presentation

- Tonnage sold : around 20,000 tonnes

- Building surface area : 32,000 sq.m

- Land surface area : 23 hectares

- Certifications : IFS

BRC

OHSAS 18001

ISO 14001

- Building surface area : 32,000 sq.m

- Land surface area : 23 hectares

- Certifications : IFS

BRC

OHSAS 18001

ISO 14001

The cheese factory Henri Hutin practices Lean Manufacturing, we talk about Industrial Performance Improvement.

Lean is a collaborative global approach which focus on continuous elimination of non-added values and on the sustainability of the company through Human development and Customer satisfaction.

Through a systematic approach of continuous improvement, with each employee contribution and using the Lean tools, the company is making progress.

At Henri Hutin cheese factory, everyone is responsible for managing the process successfully.

Lean is a collaborative global approach which focus on continuous elimination of non-added values and on the sustainability of the company through Human development and Customer satisfaction.

Through a systematic approach of continuous improvement, with each employee contribution and using the Lean tools, the company is making progress.

At Henri Hutin cheese factory, everyone is responsible for managing the process successfully.

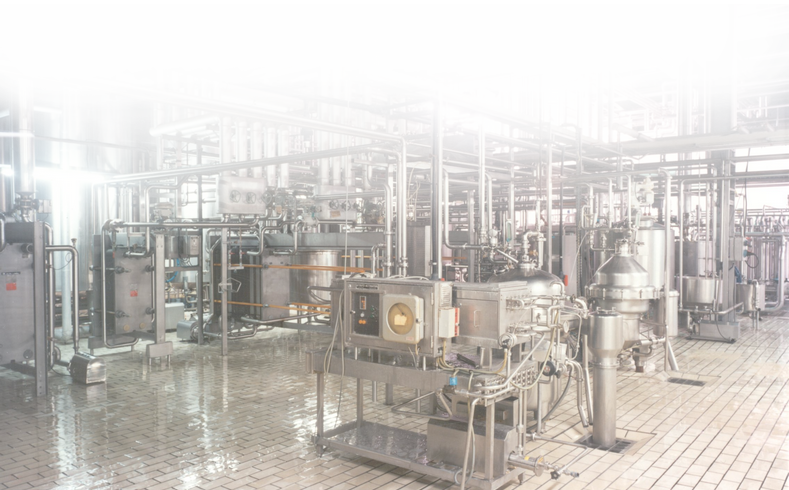

Milk Processing Plant

- Milk processing capacity : 800,000 litres by day

- Current processing : 150 millions litres of milk a year

- Standardisation of protein, fat and calcium content and of pH values

- Pasteurisation

- Production of starter cultures

- CIP management: automatic Cleaning In Place

- Current processing : 150 millions litres of milk a year

- Standardisation of protein, fat and calcium content and of pH values

- Pasteurisation

- Production of starter cultures

- CIP management: automatic Cleaning In Place

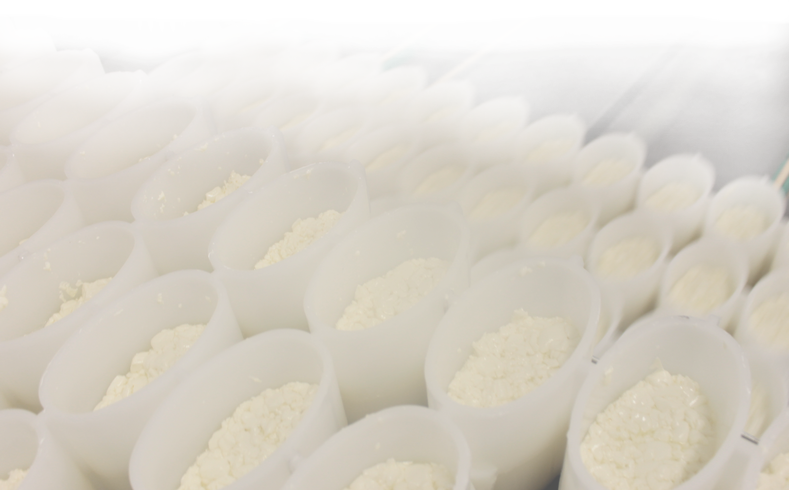

Soft Ripened Cheese Plant

- 45 metre-long coagulator

- Production capacity : approximately 25,000 tonnes a year

- Production of soft ripened cheese specialities, plain or flavoured Brie intended

for sale in portions or whole

- Ripening rooms: maturing takes between 7 and 10 days depending on the category, and our ripening

rooms have a total capacity of 30,000 tonnes a year

- Production capacity : approximately 25,000 tonnes a year

- Production of soft ripened cheese specialities, plain or flavoured Brie intended

for sale in portions or whole

- Ripening rooms: maturing takes between 7 and 10 days depending on the category, and our ripening

rooms have a total capacity of 30,000 tonnes a year

Pressed Soft Ripened Cheese Plant

- Production of plain and flavoured cheese logs weighing 5.5 kg

- Production capacity: more than 4,000 tonnes a year

- Ripening rooms: maturing takes between 7 and 10 days depending on the category.

- Production capacity: more than 4,000 tonnes a year

- Ripening rooms: maturing takes between 7 and 10 days depending on the category.

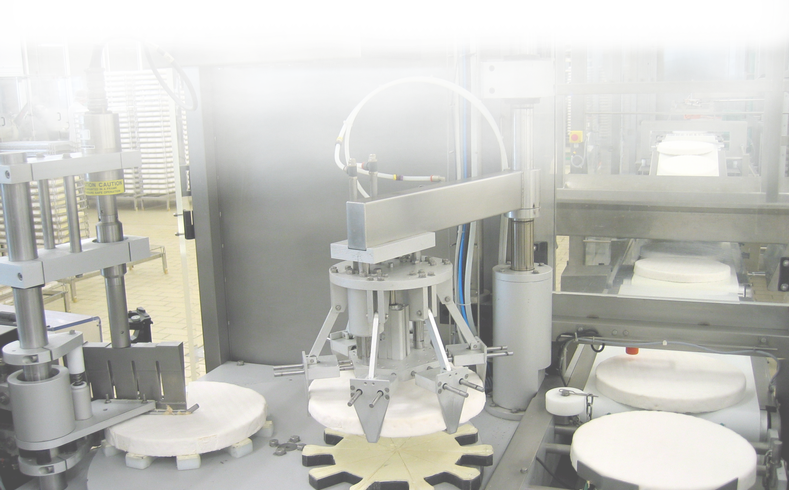

Spreadable Fresh Cheese Plant

- 3 plain and flavoured spreadable fresh cheese production lines

- 3 packaging lines

- Production capacity : more than 3,000 tonnes of cheese a year

- 3 packaging lines

- Production capacity : more than 3,000 tonnes of cheese a year

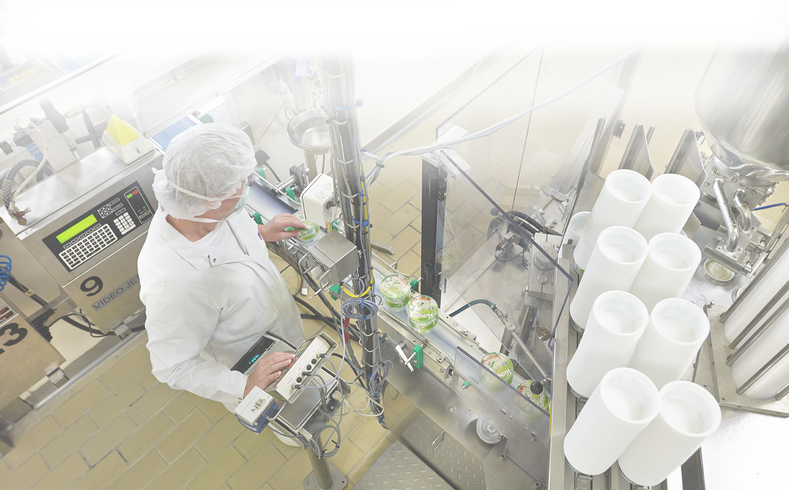

Packing Workshop

- 9 packaging lines

- including 4 lines for cutting whole Bries into Brie portions

- 1 line for packing whole Bries

- 3 lines for oval-shaped soft ripened cheese specialities

- including 4 lines for cutting whole Bries into Brie portions

- 1 line for packing whole Bries

- 3 lines for oval-shaped soft ripened cheese specialities

General Manager :

Phone :

Address :

Capital :

Legal structure :

SIREN (Company ID No.) :

APE (Company activity code) :

VAT No. :

Hosted by :

Webmaster :

Josef STITZL

03.29.87.23.23

Fromagerie Henri Hutinrue du Rattentout55320 Dieue-sur-meuse

1.500.000 €

485.920.227 R.C.S. Bar-le-Duc

485.920.227.00033

1051C

FR73485920227

1 hébergement400 avenue RoumanilleBP 6017706903 Sophia AntipolisCedex - FR

IT dept. - Fromagerie Henri Hutin

Terms & Conditions - Fromagerie Henri Hutin

HistoryThe GroupOur CustomersOur Values

R&D InnovationQualityProduction ToolThe Environment

Our soft ripened cheeses - Large formatsOur soft ripened cheeses - Small formatsOur pressed soft ripened cheesesOur spreadable fresh cheeses

Our ProfessionsPositions vacantWork experience and work/study programmesGreat Place To Work

French MilkLand of HistoryHow is cheese made?

Site map - Fromagerie Henri Hutin